Porcelain Insulator News

by Elton Gish, NIA #41

Reprinted from "Crown Jewels of the Wire", November 1989, page 19

Two very unusual insulators have turned up in the past year which I have

neither seen nor heard reported. The first insulator is U-384B and is pictured

below. It does not appear unusual in the black-and-white photo, but what makes

it so different is that it has a beautiful medium blue glaze! Not cobalt blue.

The only colors that have been reported for any of the helmet styles has been

white and shades of brown. The glaze on this specimen is transparent which

allows marks on the surface of the porcelain body to show through.

I thought

that this insulator may be unique (one-of- a-kind) until I checked with Chris

Hedges. He has one identical to this one, even down to the various lines made by

the trimmer blade, mold imperfections, and the braided lines and cuts on each

ear. It is like looking at similar fingerprints. The mark on the dome is not a

manufacturer's marking and it is difficult to determine the manufacturer. Are

there any other blue helmets out there?

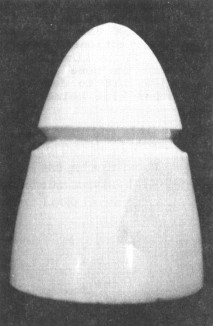

This year, at the Cedar Rapids Regional, a very rare, historic insulator

traded hands. Yet, few who attended the show were aware of the significance of

this find or they were not familiar with Pass & Seymour and their historic

first in the manufacture of wet process porcelain insulators. Russ Hughes had acquired

this insulator in a collection he purchased from an eastern Colorado collector.

The style is shown in Jack Tod's book, Porcelain Insulators Guide Book, as

U-146. "Just a common white beehive1', you might say. Well, that is the

farthest from the truth as one can get. This insulator was thought to be

nonexistent! So, what is so special about this white beehive?

In Jack's original

research trips back east, he was able to acquire from Pass & Seymour (they

are still in business) a copy of a page from their 1892 catalog which shows the

U-146 as well as U-141. By the way, U-141 is still unknown. Jack's intuitive

drawing hand is amazing as the dimensions and shape of the U-146 drawing, that

he made from the catalog drawing, match perfectly with the real thing! To see

what I am talking about, this catalog page is reproduced in Jack Tod's book

under the history of Pass & Seymour. There is no question about this being a

Pass & Seymour product as the bullet shape is very distinctive.

This only

known specimen of U-146 is perfectly mint with a fine white glaze characteristic

of early wet process manufacture such as that of Imperial. The entire insulator

Is the finest example of the ceramist's art that I have ever seen.

Pass &

Seymour was the first to make wet process porcelain and the first to

successfully thread porcelain. This later fact was announced in the November 16,

1891 issue of the Electrical Engineer. Threading of porcelain was a major

breakthrough which provided the potential for porcelain insulators to be able to

compete with glass insulators. The wet process porcelain, developed by Pass

& Seymour, has been referred to ever since as "Syracuse China". The

various beehive styles they produced were made by casting. The casting process

has found limited use in the manufacture of insulators, usually reserved for

difficult shapes such as the Spiral (U-820) and the Jeffery-Dewitt two-skirter

uniparts.

U-141 shown in the 1892 Pass & Seymour catalog is still unknown.

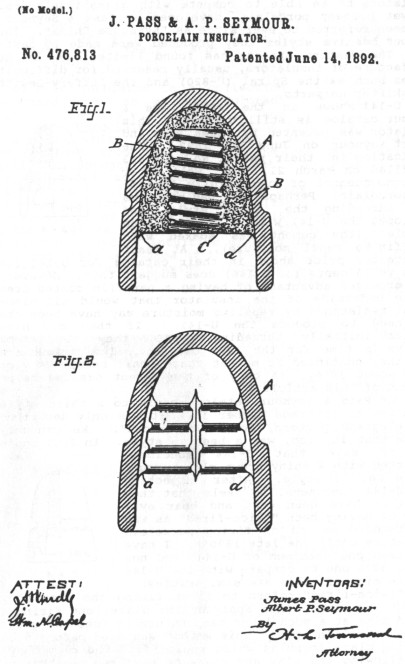

This insulator was patented by James Pass and Albert Seymour on June 14, 1892.

The application for their patent No. 476,813 was filed on March 21, 1892, well

after the announcement of successfully threading porcelain. Perhaps they had

problems with threading the U-146 style, and developed the U-141 with a cemented

lead thimble (the cement was soaked with paraffin to repel moisture). At least

the greater price shown in their catalog for U-141 (18 cents vs 13 cents for

U-146) does suggest that. However, the perceived advantage of having a paraffin

coated area on the underside of the insulator that would aid electrical

resistance by repelling moisture may have been the sole need to produce the

U-141. If they did have problems initially threading U-146, they were soon

resolve in time for the 1892 catalog. Indications are that they continued to

market these small beehive styles until about 1896. (A copy of the patent

drawing is at the end of this article.)

The Pass & Seymour catalog refers to

a third style which was their trade number 16. It was only described as

"telegraph pattern, double petticoat". We can only assume that it, too,

was a beehive style. In Jack Tod's book, he says that U-144 specimens (unmarked

with a shiny brown glaze) could be the No. 16 style. After inspecting many U-144

specimens, he feels that they appear to have been cast and bear evidence of

having been "twice-fired" as was the standard method of firing

porcelain insulators until the late 1890's. I have only seen one specimen of

U-144, and now do not have one to compare with the U-146 to determine if there

are similarities.

"Twice-fired" refers to first firing the clay body

without the glaze, then applying the glaze, and firing a second time at a much

lower temperature to fuse the glaze to the porcelain body. This method was used

before discovering glaze formulas which would "fit" the clay body,

thus allowing the clay and glaze to be fired together at the same temperature.

Specimens made by Imperial indicate that they continued to

"twice-fire" as late as 1899.

Large Image (132 Kb)

|